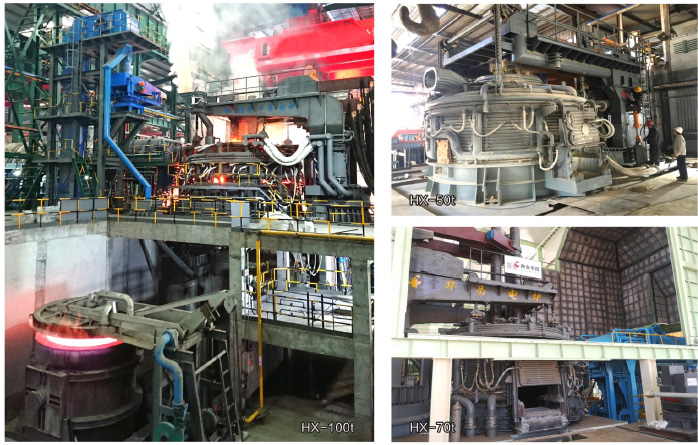

Main uses: For melting kinds of alloy steels,stainless steel,carbon structural steel and quality carbon steel.

Device features: HX series arc furnace is open cover and filled from top.It is divided into common power,superpower,ultra high power according to the adaption;it is divided into left operation and right operation according to the operation mode;the tapping form includes:tapping from spout and tapping from the eccentric bottom.

Device components: Furnace body,high current system,tilting furnace mechanism,electrode lifting mechanism,cover up rotating mechanism,Water-cooled system,hydraulic system,high-voltage system,electric furnace transformer,low-voltage system, automatic control system.

The main technical parameters

| Type | Inner Diameter of Furnace Body | Capacity(t) Rated/Maximum | Transformer | Reactor Capacity (K Var) | Diameter of the Electrode Distribution Circle (mm) | Electrode Diameter (mm ) | |

| Capacity (MVA) | 二次电压(V) | ||||||

| HX-0.5 | 1700 | 0.5/1 | 0.63 | 200~98 | 120 | 620 | 150 |

| HX-3 | 2700 | 3/5 | 2.2 | 210~104 | 260 | 750 | 250 |

| HX-5 | 3200 | 5/8 | 3.2 | 221~110 | 320 | 850 | 300 |

| HX-10 | 3500 | 10/15 | 6.3 | 260~139 | 360 | 1000 | 350 |

| HX-15 | 3800 | 15/20 | 8 | 260~139 | 360 | 1000 | 350 |

| HX-20 | 4000/4200 | 20/25 | 12.5 | 340-308-195 | 1050 | 400 | |

| HX-30 | 4600 | 30/45 | 25 | 570~430~350 | 4000 | 1100 | 450 |

| HX-40 | 4800 | 40/60 | 32 | 650-500-350 | 6800 | 1100 | 450 |

| HX-60 | 5200 | 60/75 | 35 | 670-520-370 | 7800 | 1150 | 500 |

| HX-75 | 5600 | 75/95 | 50 | 800-650-400 | 9800 | 1250 | 550 |

| HX-100 | 6200 | 100/120 | 50 | 800~650~400 | 9800 | 1250 | 500 |

| 63 | 920-720-480 | 13000 | 1350 | 600 | |||

| HX-120 | 6400 | 120/140 | 63 | 920~720~480 | 13000 | 1350 | 600 |

| 80 | 1100~800~520 | 16000 | 1350 | 600 | |||

Remark: These Parameters can be adjusted according to the different process requirements.